LNG Canada Export Terminal

Project Overview

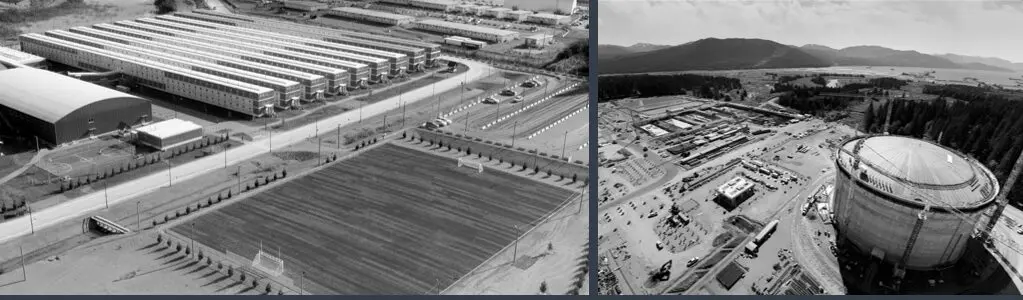

The LNG Canada project in Kitimat, British Columbia, is the largest energy investment in Canadian history. This globally recognized project includes the design and construction of a state-of-the-art Liquefied Natural Gas (LNG) export terminal. The 400-hectare facility housing a natural gas receiving terminal, LNG production units, storage tanks, a rail yard, water treatment systems, and a marine terminal, enabling the export of surplus Canadian natural gas to meet global energy demands.

What started as a small desktop tenure research project has expanded to supporting early works with planning topographic surveys to a three-crew QA/QC scope in the early stages of site construction, to the survey of various complex and intricate underground systems, above-ground piles and infrastructure, heavy haul roads, and stockpiles. This project is truly one of a kind, and GeoVerra is proud to be a part of it right from the start. GeoVerra’s contribution to this transformative energy project underscores its commitment to precision and innovation in geomatics.

Project Background

Located in Kitimat, LNG Canada is a large-scale export facility. It is the first of its kind in the country and the largest private sector investment in Canadian history. It involves liquefying natural gas for export, primarily to Asian markets, and is expected to export 14 million tonnes of LNG annually.

Why GeoVerra

Creative Geospatial Solutions

GeoVerra demonstrated exceptional creativity in geospatial solutions to meet the unique demands of the LNG Canada project. Operating under a Special Flight Operations Certificate (SFOC) approved by Transport Canada, GeoVerra’s RPAS pilots can fly at higher altitudes, enabling precise imagery capture within narrow weather windows. Beyond aerial operations, GeoVerra deployed advanced geospatial techniques, including UAV flyovers for volume and imagery analysis, bathymetric monitoring using the Echoboat and single-beam echosounder to map ocean floors for safe vessel docking, and daily high-precision monitoring of facility structures. By leveraging expertise across multiple business lines, GeoVerra delivers a comprehensive, first-class geospatial service, solidifying its reputation for overcoming complex surveying challenges.

Capacity, Communication and Safety

With management support from both BC and Alberta, and crew and office support nationwide, GeoVerra scaled up to have team members from across the company committed to this project. Communication is vital to the success of any project, from the office to the field, as GeoVerra showcased. Meetings between management and the client were conducted weekly and often daily on-site. All field staff attended daily field crew safety and workflow meetings to proactively address potential hazards on site and ensure tasks were completed efficiently. Proactive reporting was also recognized as an essential part of the site dynamic, with on-site staff completing several reports per week, with top performers recognized through the project’s safety program.

Primary Services

- Construction surveying

- Control surveys

- UAV LiDAR, orthophotography, aerial

- Legal and topographic surveys

- Underground utility locating

- GIS mapping

- 3D scanning

- As-built surveys

- Monitoring and deformation surveys

- Underground facility database management

- Photography and videography

- Quality Assurance

Deliverables

Our team provided comprehensive surveying, quality assurance, and digital documentation services to support transparency, accuracy, and informed decision-making throughout the project lifecycle. Key deliverables included:

- Interactive Visual Documentation Portal: Recurring visual documentation of critical construction activities shared through an interactive online platform, enabling remote site visits as a safer, more cost-effective alternative to in-person inspections while maintaining full project transparency.

- Survey QA & Standards Compliance Reporting: Development of detailed Quality Survey Reports (QSRs) evaluating third-party survey contractors against site geodetic standards. This included field audits, equipment usage reviews, calibration checks, methodology assessments, surveyor knowledge testing, and verification of overall geodetic compliance.

- Building & Land Deformation Monitoring: Heat maps illustrating structural and ground deformation, providing stakeholders with clear insights into movement trends and potential areas of concern.

- Quality Control Reviews: Independent QC reports analyzing deliverables from other survey companies to ensure accuracy, consistency, and compliance with project requirements.

- Comprehensive As-Built Documentation: As-built spreadsheets and supplemental sketches for all construction utilities, including cathodic protection systems, underground electrical, piping networks, and drainage.

- Civil Earthworks Monitoring: Routine heat maps showing conformance to design, highlighting areas requiring contractor attention, as well as cut/fill volume reports for remaining earthworks.

- Structural Conformance Reports: Verification of structural layouts, design adherence, and recommendations for redesigns or technical adjustments as required.

- Digital Integration-Ready Data: All deliverables provided in digital formats optimized for compatibility with GIS and CAD platforms, ensuring seamless integration into broader project systems.

Ready to Start?

As one of Canada’s largest geomatics companies, we have field offices dotted from British Columbia to Ontario so that we can deploy teams with local knowledge at the drop of a hat and scale quickly to meet project needs.